Laser engraving can improve the efficiency of carving, making the surface of the carved area smooth and round, quickly reducing the temperature of the non-metallic material being carved, reducing the deformation and internal stress of the carved object; According to the different laser sources, they can be divided into CO2 non-metallic laser engraving machines and fiber optic metal engraving machines. CO2 non-metallic laser engraving machines generally use glass laser tubes in China, and some high-end laser engraving machines also use CO2 metal RF tubes.

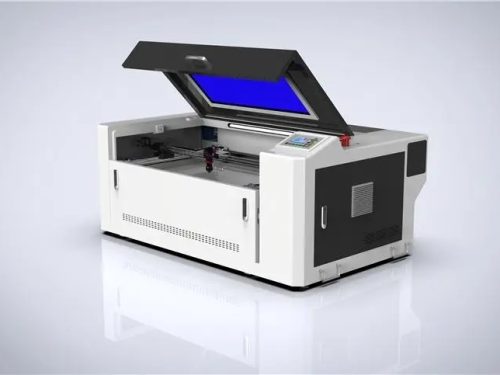

Laser engraving machine, as the name suggests, is an advanced device that uses lasers to carve materials that need to be carved. Laser engraving machines are different from mechanical engraving machines and other traditional manual carving methods. Mechanical engraving machines use mechanical means, such as diamonds and other materials with extremely high hardness, to carve other things.

The laser engraving machine uses the thermal energy of the laser to carve materials, and the laser inside the laser engraving machine is its core. Generally speaking, laser engraving machines have a wider range of applications, higher carving accuracy, and faster carving speed. Moreover, compared to traditional manual carving methods, laser carving can also achieve a very delicate carving effect, no less than the level of manual carving technology. It is precisely because laser engraving machines have so many advantages that the application of laser engraving machines has gradually replaced traditional engraving equipment and methods. Becoming the main carving equipment.