What Are the Benefits of Using a CO2 Laser Cutter in Ireland?

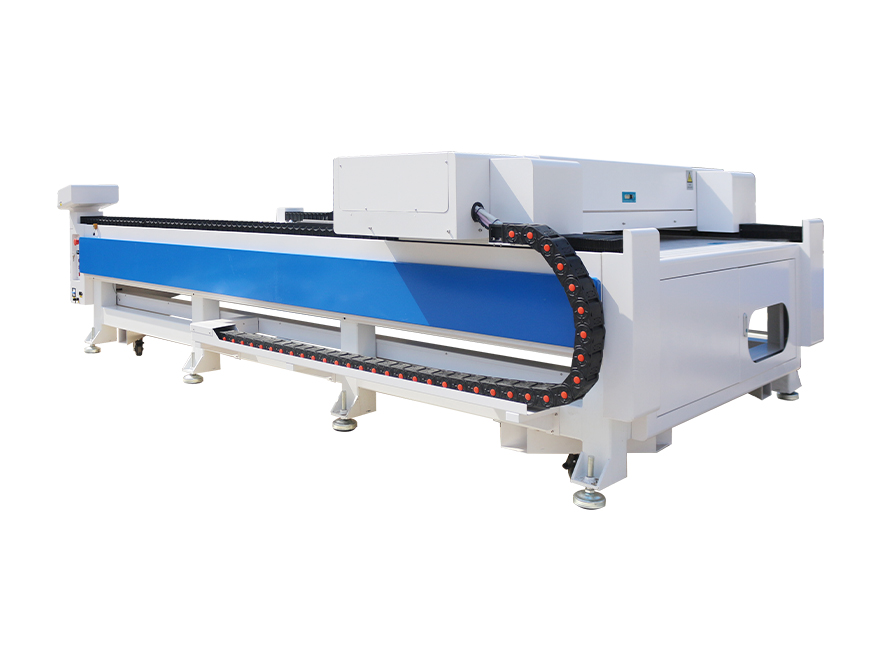

The CO2 laser cutter is a powerful and versatile machine that has become increasingly popular among industries in Ireland. This cutting-edge technology provides a range of advantages over more traditional methods, and can be used to create high-quality components with high precision and accuracy. In this article, we explore the key benefits of using a CO2 laser cutter in Ireland.

High Precision and Accuracy

The most obvious advantage of using a CO2 laser cutter in Ireland is the level of precision and accuracy that can be achieved. By using a sophisticated laser that is more powerful than traditional methods, intricate and intricate shapes can be cut with extreme accuracy. This allows manufacturers to create components that are perfectly tailored to the specific dimensions they require.

Lower Material Costs

The use of a CO2 laser cutter can also help to reduce material costs by reducing the amount of wastage due to inaccurately-cut components. The laser can precisely cut through the material without excess waste, which means only the exact amount of material needed is used. This can result in significant cost savings over time.

Lower Production Time

Using a CO2 laser cutter in Ireland can also reduce the time needed to create components. The laser is capable of quickly and accurately cutting through the material in a single pass, reducing production times compared to traditional methods. This can help to speed up the overall production process and enable manufacturers to meet the demands of their customers.

Flexible Design Options

The CO2 laser cutter can also provide manufacturers with flexible design options. The laser cutting process can be used to create complex components with intricate shapes and patterns that would not be accessible through traditional methods. This means that the design possibilities are almost limitless and manufacturers can easily create components that are tailored to their exact specifications.

Versatility

The CO2 laser cutter is also a highly versatile tool that can be used to cut a range of different materials. Many different metals, plastics, and even materials such as glass and wood can easily be cut using a laser. This makes it an essential tool for a wide range of industries.

Environmentally-Friendly Technology

The CO2 laser cutter is also an environmentally-friendly technology. The lasers do not produce any hazardous chemicals or fumes, meaning they can be safely used without impacting the environment. This is a major benefit compared to traditional methods which can produce a large amount of waste that can be damaging to the environment.

FAQs

Q: What materials can be cut with a CO2 laser cutter?

A: The CO2 laser cutter can be used to cut a wide range of materials, including metals, plastics, wood, and even glass.

Q: How accurate is a CO2 laser cutter?

A: The laser used in a CO2 laser cutter is extremely accurate, and can provide precision down to a fraction of a millimetre.

Q: Are CO2 laser cutters environmentally-friendly?

A: Yes, CO2 laser cutters are an environmentally-friendly technology as they do not emit any hazardous chemicals or fumes.