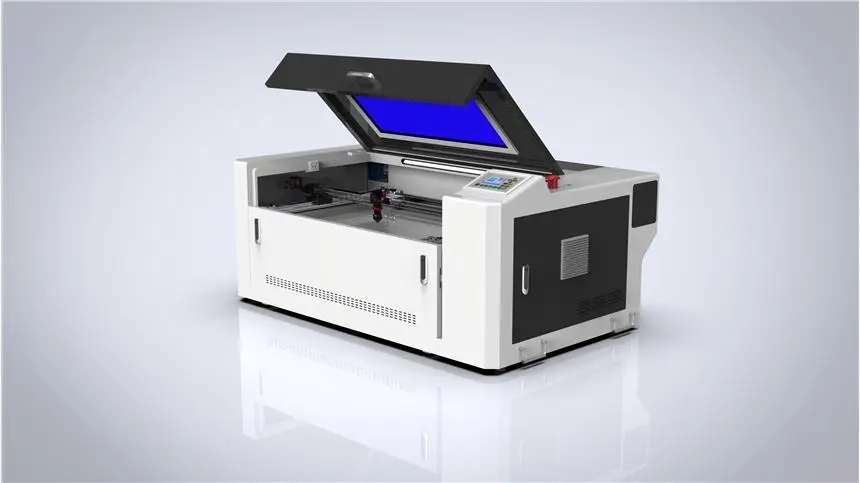

If you own a CO2 laser cutter, you know the importance of keeping it running at maximum efficiency. Upgrading your machine can help you increase production and reduce downtime, ultimately saving you time and money in the long run. Here are some tips on how to upgrade your CO2 laser cutter for maximum efficiency:

Upgrade Your Control Software

One key way to upgrade your CO2 laser cutter is by updating the control software. Newer software versions often come with improved features and functionalities that can enhance the performance of your machine. Look for software updates from your machine’s manufacturer and consider investing in a third-party software that can provide additional capabilities.

Upgrade Your Laser Tube

The laser tube is the heart of your CO2 laser cutter, and upgrading to a higher-quality tube can significantly improve cutting and engraving performance. Consider replacing your old tube with a new one that has a higher power output and longer lifespan. This upgrade can enhance the precision and speed of your machine’s operations.

Upgrade Your Cooling System

Efficient cooling is critical for maintaining the performance and longevity of your CO2 laser cutter. Upgrading your cooling system with a more powerful and reliable unit can help regulate the temperature of the laser tube more effectively, preventing overheating and potential damage to the machine.

Upgrade Your Exhaust System

Proper ventilation is essential for a CO2 laser cutter to operate at its best. Upgrading your exhaust system with a more efficient and reliable unit can help remove fumes and debris more effectively, ensuring a cleaner and safer working environment. This upgrade can also prolong the lifespan of your machine’s internal components.

Upgrade Your Worktable

If your CO2 laser cutter is equipped with a worktable, consider upgrading it to one with a higher load capacity and improved flatness. This can provide better support for your materials and enhance the accuracy and consistency of your cuts and engravings.

Upgrade Your Safety Features

Lastly, consider upgrading your machine’s safety features to ensure the well-being of your operators and the longevity of your CO2 laser cutter. This may include adding additional safety interlocks, emergency stop buttons, and laser safety glasses to minimize the risk of accidents and injuries.

Conclusion

Upgrading your CO2 laser cutter can help you achieve maximum efficiency and productivity. Whether you choose to upgrade your control software, laser tube, cooling system, exhaust system, worktable, or safety features, investing in these upgrades can lead to significant improvements in the performance and longevity of your machine.

FAQs

Q: How often should I upgrade my CO2 laser cutter?

A: The frequency of upgrades depends on the usage and maintenance of your machine. It’s important to regularly assess the performance of your CO2 laser cutter and consider upgrades as needed.

Q: Can I perform the upgrades myself?

A: Some upgrades, such as software updates, can be done by the user. However, for more complex upgrades, it’s recommended to seek professional assistance to ensure proper installation and integration with your machine.

Q: Are upgrades worth the investment?

A: Yes, upgrades can significantly improve the efficiency and performance of your CO2 laser cutter, ultimately saving you time and money in the long run. It’s important to carefully consider the potential benefits before making any upgrades.