The Pros and Cons of Plasma Cutters and CO2 Lasers

Plasma cutters and CO2 lasers are two of the most popular tools used in metal fabrication. Both tools have their advantages and disadvantages, and it is important to understand the differences between them before making a decision on which one to use.

Plasma Cutters

Plasma cutters are a type of cutting tool that uses a high-velocity stream of ionized gas to cut through metal. They are relatively inexpensive and easy to use, making them a popular choice for many metal fabrication projects.

Pros:

- Inexpensive and easy to use

- Can cut through a variety of metals

- Can cut through thick materials

- Can be used for intricate designs

Cons:

- Can produce a lot of heat and sparks

- Can be difficult to control

- Can be noisy

- Can produce a rough cut

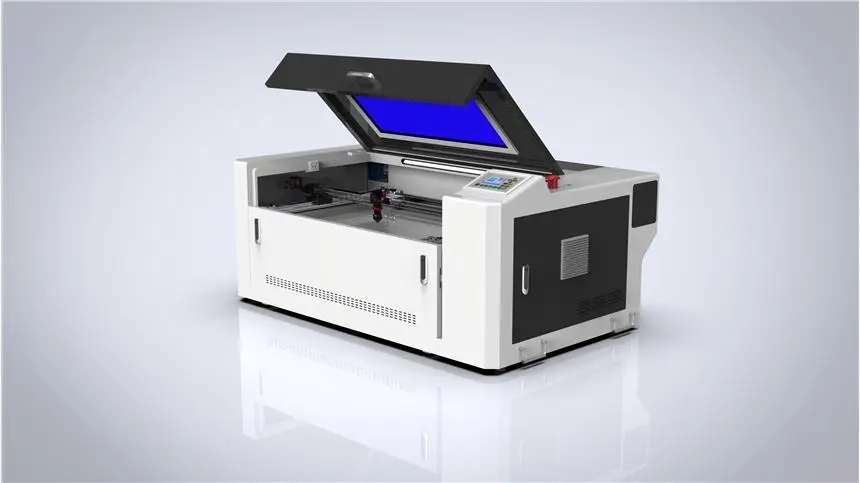

CO2 Lasers

CO2 lasers are a type of cutting tool that uses a beam of light to cut through metal. They are more expensive than plasma cutters, but they offer a higher level of precision and accuracy.

Pros:

- High level of precision and accuracy

- Can cut through a variety of metals

- Can cut through thick materials

- Can be used for intricate designs

Cons:

- Expensive

- Can be difficult to control

- Can be noisy

- Can produce a rough cut

FAQs

What is the difference between a plasma cutter and a CO2 laser?

A plasma cutter uses a high-velocity stream of ionized gas to cut through metal, while a CO2 laser uses a beam of light to cut through metal. Plasma cutters are less expensive and easier to use, while CO2 lasers offer a higher level of precision and accuracy.

Which is better for intricate designs?

Both plasma cutters and CO2 lasers can be used for intricate designs. However, CO2 lasers offer a higher level of precision and accuracy, so they may be better suited for more complex designs.