Introduction

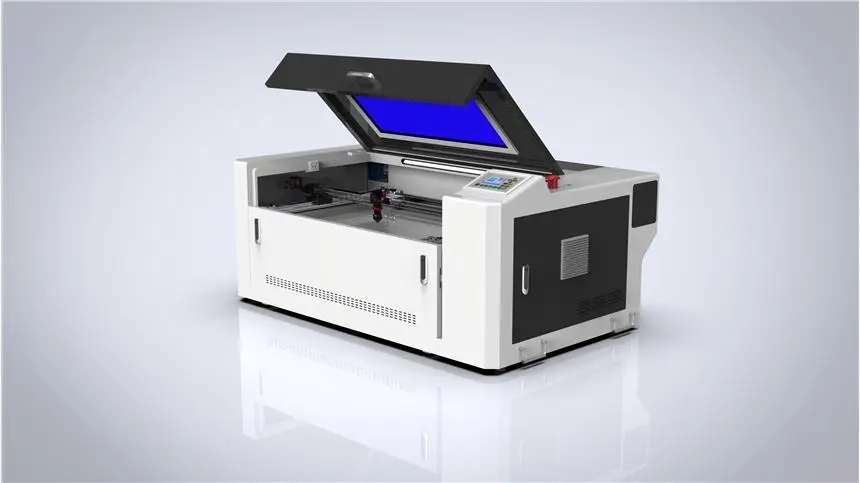

If you’ve recently purchased a CO2 laser cutter, you’re probably excited to start using it for all your cutting and engraving projects. However, setting up a CO2 laser cutter can be a bit overwhelming for beginners. In this guide, we’ll walk you through everything you need to know to get your CO2 laser cutter up and running.

Step 1: Unpacking and Assembly

When your CO2 laser cutter arrives, you’ll need to carefully unpack it and assemble any components that may not come pre-assembled. It’s important to follow the manufacturer’s instructions for this step to ensure that your laser cutter is set up properly.

Step 2: Connecting to Power and Air

Once your laser cutter is assembled, you’ll need to connect it to a power source and, if it requires it, to an air compressor. Again, it’s crucial to follow the manufacturer’s instructions to ensure that everything is connected correctly.

Step 3: Installing Software

Most CO2 laser cutters come with proprietary software that you’ll need to install on your computer. This software will allow you to design and control your cutting and engraving projects. Make sure to install the software according to the manufacturer’s instructions.

Step 4: Calibrating the Laser Cutter

Before you start cutting or engraving, you’ll need to calibrate your laser cutter. This involves adjusting settings such as power, speed, and focus to ensure that your cuts and engravings are precise and accurate.

Step 5: Safety Precautions

Before you start using your CO2 laser cutter, it’s crucial to familiarize yourself with all safety precautions. This includes wearing protective eyewear, ensuring proper ventilation, and being mindful of potential fire hazards.

FAQs

Q: Can I use my CO2 laser cutter with any material?

A: CO2 laser cutters are designed to work with a variety of materials, including wood, acrylic, leather, and paper. However, it’s important to check the specifications of your specific laser cutter to ensure that it is compatible with the material you want to use.

Q: Do I need any special ventilation for my CO2 laser cutter?

A: Yes, it’s important to have proper ventilation when using a CO2 laser cutter. This will help to remove any fumes or particles that may be created during the cutting and engraving process.

Q: How often should I perform maintenance on my laser cutter?

A: It’s important to regularly clean and maintain your CO2 laser cutter to ensure that it continues to work properly. Follow the manufacturer’s guidelines for recommended maintenance tasks.