The Benefits of Upgrading Your CO2 Laser Cutter Software

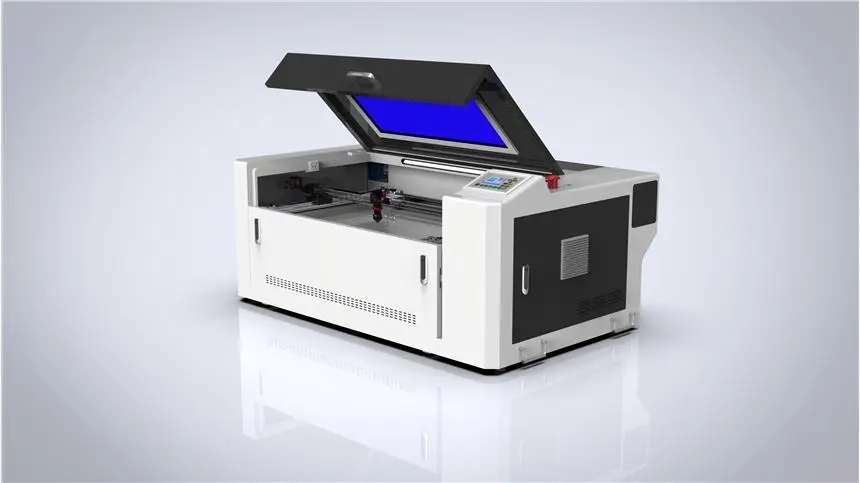

In today’s fast-paced manufacturing environment, staying ahead of the competition requires using the latest technology. If you are using a CO2 laser cutter, you know how crucial the software is in maximizing the machine’s capabilities. Upgrading your CO2 laser cutter software can bring a range of benefits that can improve productivity, reduce downtime, and increase the quality of your products. In this article, we will explore the advantages of upgrading your CO2 laser cutter software.

Improved Performance

One of the primary benefits of upgrading your CO2 laser cutter software is the improved performance it can provide. New software versions often come with updates that optimize cutting speeds, improve accuracy, and enhance the overall efficiency of the machine. This can result in significant time savings and increased throughput, allowing you to take on more projects and meet tight deadlines.

Enhanced Features

Upgrading your CO2 laser cutter software can also unlock new features and capabilities that were not available in previous versions. These features may include advanced nesting algorithms, improved job management tools, and better integration with other software or hardware systems. By taking advantage of these new features, you can streamline your workflow, reduce errors, and ultimately improve the quality of your finished products.

Compatibility with New Materials

As new materials and substrates enter the market, it’s important to ensure that your CO2 laser cutter can effectively process them. Upgrading your software can provide support for a wider range of materials, including composites, plastics, and metals. This can open up new opportunities for your business and allow you to take on a more diverse set of projects.

Increased Security and Stability

Software upgrades often come with improved security features and bug fixes that can reduce the risk of system failures and downtime. By staying up to date with the latest software version, you can minimize the likelihood of software crashes and keep your production running smoothly.

FAQs

Q: How often should I upgrade my CO2 laser cutter software?

A: It is advisable to upgrade your CO2 laser cutter software whenever a new version is released by the manufacturer. This will ensure that you have access to the latest features and improvements.

Q: Do software upgrades require additional training for operators?

A: While some upgrades may introduce new features that require training, most software updates are designed to be backward compatible and should not require extensive retraining for operators.

Q: Can I upgrade my CO2 laser cutter software myself, or do I need to contact the manufacturer?

A: It is recommended to work with the manufacturer or an authorized distributor to perform the software upgrade, as they can ensure that the process is carried out correctly and that any necessary adjustments are made to the machine.