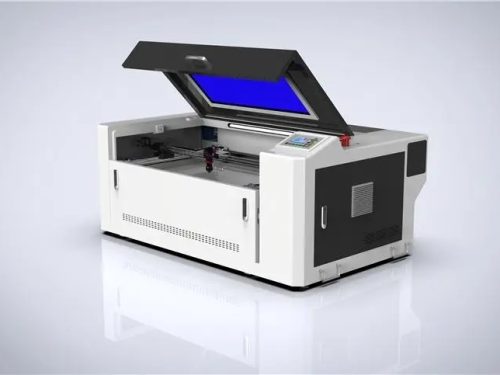

How to Choose the Best CO2 Laser Engraver Cutter

CO2 laser engraver cutters are a great tool for a variety of applications, from engraving and cutting to marking and etching. But with so many different models and features available, it can be difficult to know which one is right for you. Here are some tips to help you choose the best CO2 laser engraver cutter for your needs.

Consider Your Needs

The first step in choosing the best CO2 laser engraver cutter is to consider your needs. What type of materials will you be working with? What size and shape of objects do you need to engrave or cut? Do you need a machine that can handle large or small projects? Answering these questions will help you narrow down your choices and find the right machine for your needs.

Choose the Right Power

The power of the laser engraver cutter is an important factor to consider. The higher the power, the faster the machine can work and the more precise the results will be. However, higher power machines can also be more expensive and require more maintenance. Consider your budget and the type of projects you will be working on to determine the right power for your needs.

Look for Quality Components

When choosing a CO2 laser engraver cutter, it’s important to look for quality components. Look for machines that use high-quality lenses, mirrors, and other components to ensure the best results. Also, make sure the machine is easy to use and maintain.

Compare Prices

Once you’ve narrowed down your choices, it’s time to compare prices. Look for machines that offer the features you need at a price that fits your budget. Don’t be afraid to shop around and compare prices to get the best deal.

FAQs

What is a CO2 laser engraver cutter?

A CO2 laser engraver cutter is a machine that uses a laser beam to engrave or cut materials. It is commonly used for engraving and cutting wood, plastic, metal, and other materials.

What should I consider when choosing a CO2 laser engraver cutter?

When choosing a CO2 laser engraver cutter, consider your needs, the power of the machine, the quality of the components, and the price. Make sure the machine is suitable for the type of projects you will be working on and that it fits your budget.