CO2 Laser Technology: The Future of Industrial Cutting

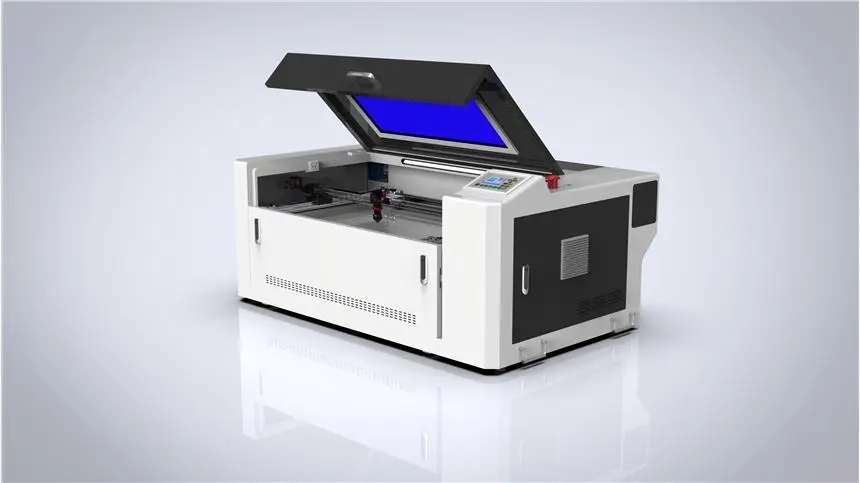

The industrial cutting industry is constantly evolving, and the latest advancement is the use of CO2 laser technology. This cutting-edge technology is revolutionizing the way industrial cutting is done, and it is quickly becoming the preferred method for many businesses.

CO2 laser technology is a type of laser that uses a beam of light to cut through materials. It is a highly precise and efficient way to cut materials, and it can be used to cut a variety of materials, including metals, plastics, and wood. The laser beam is generated by a gas mixture of carbon dioxide, nitrogen, and helium, and it is focused through a series of lenses and mirrors. This allows the laser to cut with extreme precision and accuracy.

The advantages of using CO2 laser technology for industrial cutting are numerous. It is a much faster and more efficient way to cut materials than traditional methods, and it can be used to cut materials of varying thicknesses. It is also much more precise than other cutting methods, and it can be used to create intricate designs and patterns. Additionally, it is a much safer method of cutting than traditional methods, as it does not produce any hazardous fumes or dust.

CO2 laser technology is also much more cost-effective than other cutting methods. It requires less energy to operate, and it can be used to cut materials at a much lower cost than other methods. Additionally, it is much more environmentally friendly than other cutting methods, as it does not produce any hazardous waste.

CO2 laser technology is quickly becoming the preferred method of industrial cutting, and it is revolutionizing the way businesses are cutting materials. It is a much faster, more efficient, and more cost-effective way to cut materials, and it is quickly becoming the go-to method for many businesses.

FAQs

What is CO2 laser technology?

CO2 laser technology is a type of laser that uses a beam of light to cut through materials. It is a highly precise and efficient way to cut materials, and it can be used to cut a variety of materials, including metals, plastics, and wood.

What are the advantages of using CO2 laser technology for industrial cutting?

The advantages of using CO2 laser technology for industrial cutting are numerous. It is a much faster and more efficient way to cut materials than traditional methods, and it can be used to cut materials of varying thicknesses. It is also much more precise than other cutting methods, and it can be used to create intricate designs and patterns. Additionally, it is a much safer method of cutting than traditional methods, as it does not produce any hazardous fumes or dust.

Is CO2 laser technology cost-effective?

Yes, CO2 laser technology is much more cost-effective than other cutting methods. It requires less energy to operate, and it can be used to cut materials at a much lower cost than other methods. Additionally, it is much more environmentally friendly than other cutting methods, as it does not produce any hazardous waste.