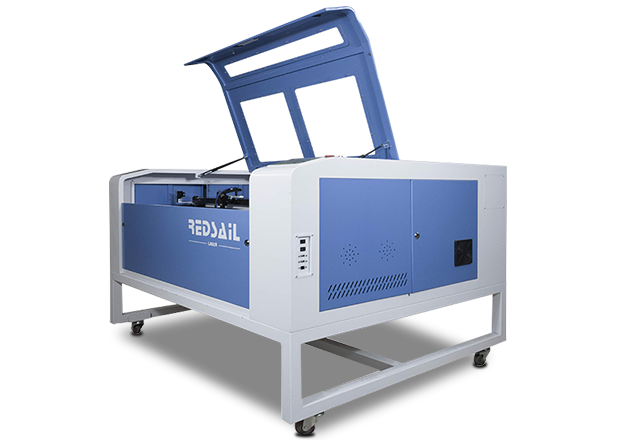

Unlock the Possibilities of CO2 Laser Cutting with Professional Services CO2 laser cutting is a powerful and versatile tool for cutting and engraving a variety of materials. It is used in a wide range of industries, from automotive to aerospace, and is becoming increasingly popular for its precision and accuracy. Professional services can help you […]