Introduction

When it comes to cutting metal, two of the most popular options are plasma cutters and CO2 lasers. Both of these tools have their own pros and cons, and choosing between them can be a bit confusing. In this guide, we will explore the differences between plasma cutters and CO2 lasers, and help you decide which one is right for your needs.

Plasma Cutters

Plasma cutters use a high-velocity jet of ionized gas to cut through metal. They are incredibly versatile and can cut through a wide range of materials, including steel, aluminum, and stainless steel. Plasma cutters are also capable of cutting through thicker materials than CO2 lasers, making them a popular choice for heavy-duty industrial applications.

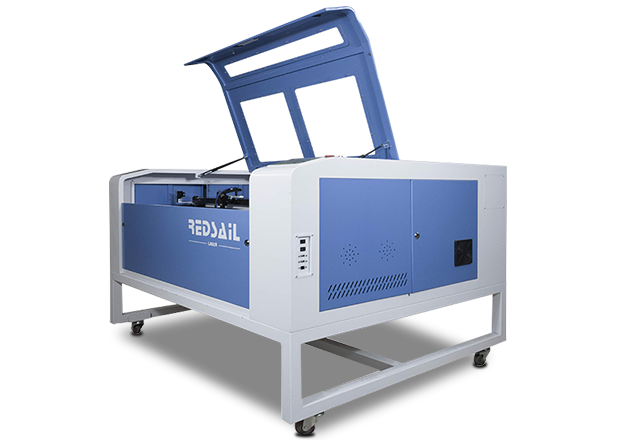

CO2 Lasers

CO2 lasers, on the other hand, use a high-powered laser beam to cut through metal. They are known for their precision and accuracy, making them a popular choice for cutting intricate designs and patterns. CO2 lasers are also capable of cutting through non-metal materials, such as wood and plastics, making them a versatile option for a wide range of applications.

Choosing Between Plasma Cutters and CO2 Lasers

When it comes to choosing between plasma cutters and CO2 lasers, it ultimately comes down to your specific needs and requirements. If you are primarily cutting thicker metal materials and need a tool that can handle heavy-duty applications, then a plasma cutter may be the best choice for you. On the other hand, if precision and versatility are more important to you, then a CO2 laser may be the better option.

FAQs

Q: Can plasma cutters cut through non-metal materials?

A: While plasma cutters are primarily designed for metal cutting, they can also be used to cut through some non-metal materials, such as plastics and rubber.

Q: Are CO2 lasers more expensive than plasma cutters?

A: In general, CO2 lasers tend to be more expensive than plasma cutters, but they also offer more precision and versatility.

Q: Which option is better for small-scale hobbyists?

A: For small-scale hobbyists, CO2 lasers may be a better option due to their precision and ability to cut through a wide range of materials.